Deodorization・VOCs Destruction Catalysts

Catalytic oxidation technology through Catalytic Combustion Systems (CCS/CatOx/CO) or Regenerative Catalytic Oxidizers (RCO) permits to properly treat the Volatile Organic Compounds (VOCs) that are responsible for atmospheric and odor pollutions.

In comparison with the existent technologies such as Direct Flame Incinerators (DFI) or Regenerative Thermal Oxidizers (RTO), CCS technology not only shows great results in terms of deodorization and VOCs destruction but also allows treatment at a relatively low temperature. Which leads to a consequent reduction of the CO2 emissions related to heating the process and contributes to the efforts to restrain Global Warming.

Advantages of Catalytic Oxidation:

- High VOC destruction efficiency (achieved over 99.999% DRE)

- Possible complete oxidation of carbon monoxide (difficult for RTO or DFI)

- Possible low temperature combustion (low fuel consumption, long equipment life)

- Feasible use of an electric heater for the RCO (CO2 reduction)

Catalyst Specifications

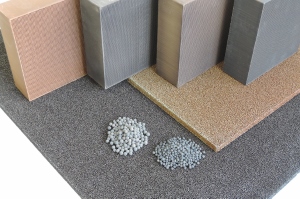

We have 3 different shapes for our catalysts: Honeycomb monolith-type (NH series), Foam-metal-type (NM series) and Spherical-type (NS series).

Depending on the client’s request, we also provide high heat-resistant catalysts, poison-resistant catalysts (including organic silicon compounds, organic phosphorus compounds, sulfurs, halogens) and other specialized catalysts, so do not hesitate to reach out to us for more information or any inquiries.

| Catalyst type | NH series | NM series | NS series | |

|---|---|---|---|---|

| Shape | Honeycomb monolith | Foam-metal | Sphere | |

| Standard size | 150×150×50t mm | 590×440×11t mm | Φ 2.5~4 mm | Φ 4~6 mm |

| Apparent bulk density | Approx. 0.7 g/cc | Approx. 0.6 g/cc | Approx. 0.4 g/cc | Approx. 0.7 g/cc |

| Catalyst allowable temperature | Pt: ~550℃ Pd: ~700℃ |

NM-1: ~550℃ NM-2: ~600℃ |

Pt: ~550℃ Pd: ~700℃ |

|

Achievements

We have a commercial tracking record of operating more than 10,000 units in Japan and overseas for VOC destruction in various processes such as painting, drying, calcination, sintering, and fermentation.

For inquiries:

| Department | Environmental Catalyst Div. |

|---|---|

| Contact Form | |

| TEL | ARIOKA:+81-90-5398-5199 (Japanese, English) PIET:+81-80-4462-6530 (French, English) *Do not hesitate to reach out to us by using the contact form, we will come back to you as soon as possible. |