Rice Cooking Plant Application

Although western style cuisine is popular these days, rice is still a staple of Japanese people. You can see many variations of cooked rice lunch packs such as ‘bento’ and ‘onigiri’ sold in supermarkets and at train stations. As these products are prepared under strict quality control systems, obvious contaminants such as hair or other foreign objects are never seen. Nevertheless, it is also important to prevent bacterial contamination which causes food poisoning and spoils the products.

In preparation areas, microorganisms can unexpectedly settle in air conditioning systems or inside air ducts. Air filters in these areas run for months or years, capturing bacteria and fungal spores as well as dust. Since production areas for rice cooking are humid, such contaminants grow easily. The problem is that those microorganisms survive inside the air filters, multiply, and finally pass into clean preparation areas. An airborne bacterium is too small to be seen with the naked eye; therefore, it is necessary to choose an appropriate air filter for manufacturing safe, high quality products.

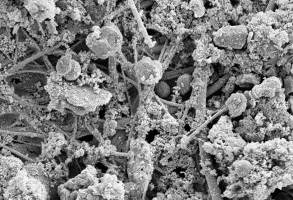

Photo 1: Heavily clogged inlet side of a Biofree Enzyme HEPA filter used for five years.

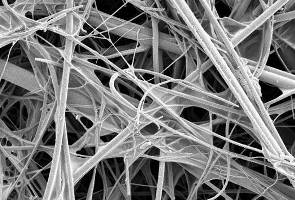

Photo 2: No microorganisms found on the outlet side of the Biofree Enzyme HEPA filter.

Photograph 1 (below) shows the intake side of an N-U Biofree brand Enzyme filter used for five years in a rice cooking factory which is heavily clogged with dust. Photograph 2, however, shows no contamination at the outlet side of the same filter. The reason for this is that a special enzyme has dissolved the cell walls of the bacteria, thus destroying them and reducing them to a molecular level. Enzyme filters can maintain their bactericidal activity for years because a natural lytic enzyme, which is safe for humans, is immobilized on the glass fibers of the filter media. As the enzyme does not flake off or elute, it continues working until the filter is replaced due to dust clogging.

It is hard to see whether or not air filters have been contaminated since they are usually placed in ducts or HVAC systems behind walls and ceilings. Using products such as Biofree Enzyme filters is a reliable and cost-effective way to support the safety and quality of your products.

We can provide optimized Enzyme filters for end users according to the facility requirements of individual factories.

Contact Sales Department

| Department | Environmental Catalyst Div. |

|---|---|

| Contact Form | |

| TEL | 81-3-5436-8491 |

| FAX | 81-3-5436-8680 |