Molding

Molding

Molding processing technology

Molding processing technology for different applications and purposes

- Extrusion

- Granulation

- Coatig

- Dropping

Physical property control technology for molded products

The following physical properties can be controlled by selecting the suitable molding process technology, optimizing process conditions, and selecting the materials and binders to be combined.

- Bulk density

- Strength

- Pore structure, specific surface area

- Water immersion fracture

(cracking property when immersed in liquid) - Diffusivity (mass transfer)

- Shape

- Thermal expansion/shrinkage

Extrusion

Extrusion: Mixing of raw material powder → knead→ Extrusion → calcining

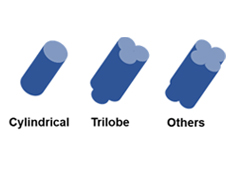

- Shape: Extrudate, Tri-lobe, etc.

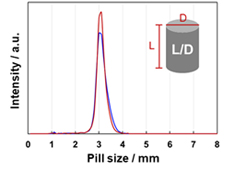

- Lengthwise uniformity cut

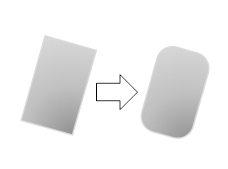

- Round off the edge of extrudate

- Prevention of powdering, improvement of filling rate

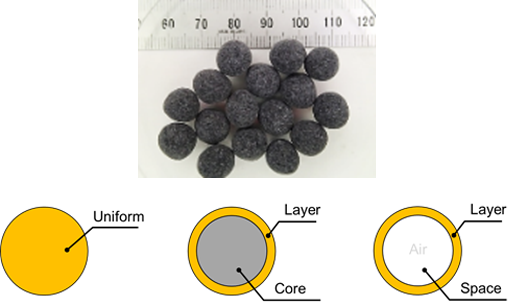

Granulation

Granulation:Mixing of raw material powders → base core → granulation → calcining

- Spherical size control

- Uniform granulation of target materials

- Core Shelling

- Hollowing

We can manufacture the following products by applying molding technology.

- Products with two reactions by two or three multi-layering

- Products with improved reactivity by binderless granulation

- Products with high geometric surface area by rough surfaces

Contact Sales Department

| Department | Business Innovation Office |

|---|---|

| Contact Form | |

| TEL | 81-3-5436-8484 |

| FAX | 81-3-5436-8680 |