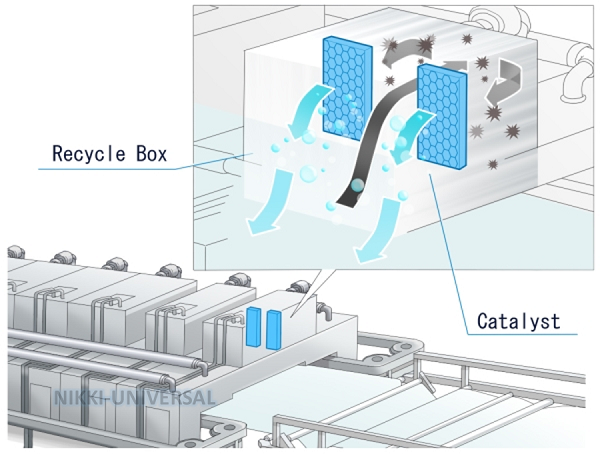

Catalysts for Oven Cleaning

PET film ovens, reflow ovens, coil coating, as well as every type of ovens release sublimates (such as oligomers, fluxes, tars, and so on). Can be treated with our oven cleaning catalysts to suppress and restrain the formation of impurities and fouling materials.

Using oven cleaning catalysts inside your ovens will effectively make use of the existing temperature without further heating (low energy treatment). It will also significantly reduce the oven cleaning frequency (and by doing so, reduce the downtime of your equipment) and improve the quality of the products (by removing impurities).

Catalyst Specifications

| Catalyst type | Oven cleaning catalyst |

|---|---|

| Shape | Honeycomb monolith |

| Cell number | 200 cells/inch2 |

| Standard size | 150×150×50t mm |

| Apparent bulk density | Approx. 0.8 g/cc |

Achievements

We have a commercial tracking record of operating PET film ovens, polyamide film ovens, polyimide film ovens, reflow ovens, aluminum sheet coil coating, and among other types of ovens.

For inquiries:

| Department | Environmental Catalyst Div. |

|---|---|

| Contact Form | |

| TEL | ARIOKA:+81-90-5398-5199 (Japanese, English) PIET:+81-80-4462-6530 (French, English) *Do not hesitate to reach out to us by using the contact form, we will come back to you as soon as possible. |