Coating

Features

We can coat various materials according to the purposes and support the catalyst components necessary for the reaction. We also provide support from trial production to mass production of catalysts according to customer needs.

- Applicable to a wide variety of catalytic support and substrates

- Coating a wide variety of raw materials

- Control the thickness of the coating layer

- Coating honeycomb not only catalytic support but also spherical catalytic support and irregular-shaped catalytic support.

- The ceramic coating on materials that are difficult to coat

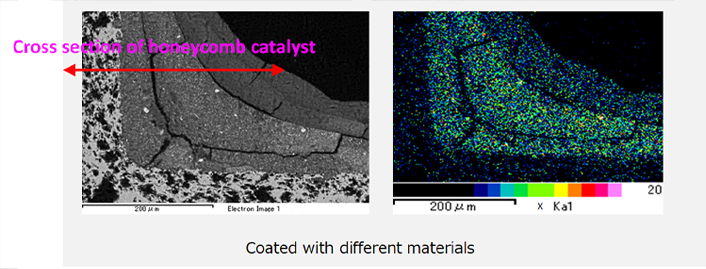

- Multiple coating layers (two layers, three layers, etc.)

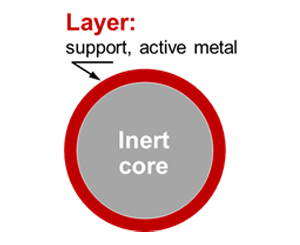

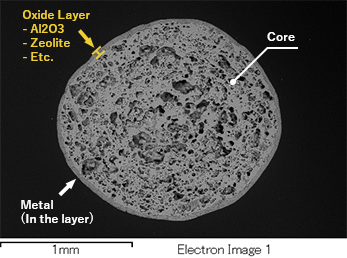

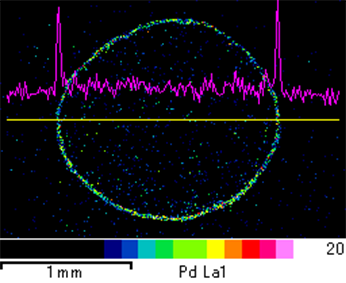

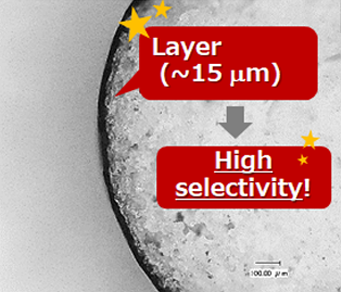

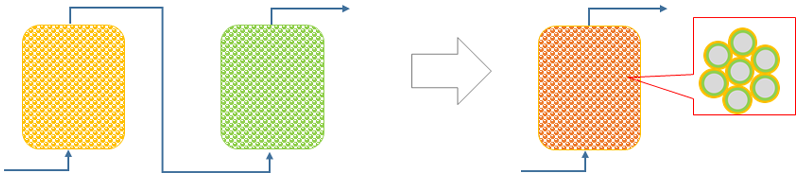

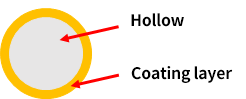

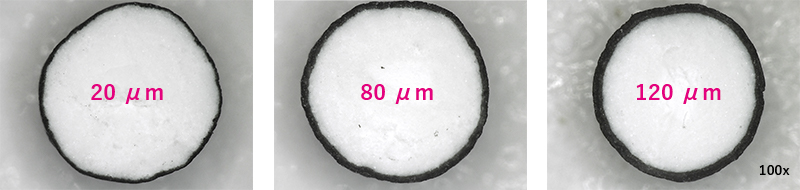

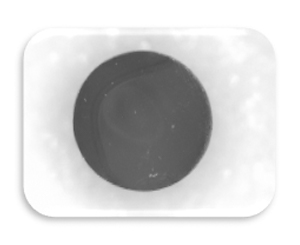

Core shell spray coating

Advantages of Core shell catalyst

- Achieve similar activity to small pills with higher performance

- Reduce the residence time to suppress the secondary reaction

- High selectivity in a partial step of a multiple step reaction.

- Cost reduction (Decrease the precious metal, zeolite, etc.)

- Adjustable layer thickness depending on target reaction

Applications

- Multi-layered of coating layer

- Control of the reaction system in a multi-layered structure and downsizing of the reaction equipment

- Hollow particleization

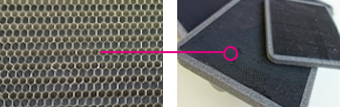

Wash coating

Other Coatings

We have experience coating various materials such as cordierite, ceramics, inorganic fibers, non-woven fabrics, aluminum, paper, rayon, etc.

- Honeycomb monolith(1,200cpsi)

- Materials that are difficult to absorb water (foam metal, aluminum honeycomb, etc.)

- Deformed materials(Raschig ring, Sand, etc.)

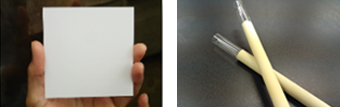

- Quartz tubes and plates

Supporting

Method

- Impregnation loading, water absorption loading

- Spray coating

- Knead-in support

- Ion exchange

Feature

- Metal distribution control

- Control of metal dispersion

- Compatible with various metals and various carriers

- Ion exchange of zeolites, etc.

Applications

- Support of materials with a high concentration exceeding the adsorption capacity

- Stabilization of supported components and control of adsorption properties.

Supporting technology

Surface supporting

- The thickness of the metal is controlled by supporting the metal only on the surface of the catalyst support.

Uniformity supporting

- Uniformity supporting to the inside of the catalyst support

Other supporting technology

- High dispersion of supported metal particles

- Grain diameter control

- Sintering control of supporting technology

- Activity control: Alloying, Attenuator

- Redox state control

Contact Sales Department

| Department | Business Innovation Office |

|---|---|

| Contact Form | |

| TEL | 81-3-5436-8484 |

| FAX | 81-3-5436-8680 |