Low Energy Consumption Catalysts

As a catalyst manufacturer and to attain carbon neutrality by 2050, we are actively doing research and development with the desire to find new solutions for our customers.

As a result of our efforts we lately released the LFW catalyst (Let’s Find a Way) whose characteristics can be found below. We are constantly trying to explore new possibilities for this catalyst so do not hesitate to contact us in order to discuss your project.

Catalyst Characteristics

- Higher activity at lower temperature than conventional catalysts

→Enable low-temperature operation for the equipment

→Contribute to energy saving and CO2 reduction - High resistance to organic silicones which are the catalysts’ greatest weakness

→Can apply to fields that typically could not use catalysts - No precious metals or harmful substances

→Sustainable (long-term and stable supply, reduction of geopolitical risks, etc.)

Catalyst Specifications

| Catalyst type | LFW series |

|---|---|

| Shape | Honeycomb monolith |

| Cell number | 200 cells/inch2 |

| Standard size | 150×150×50t mm |

| Apparent bulk density | Approx. 0.8 g/cc |

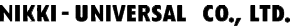

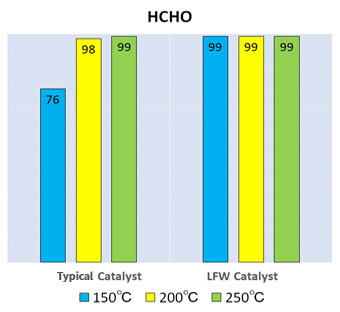

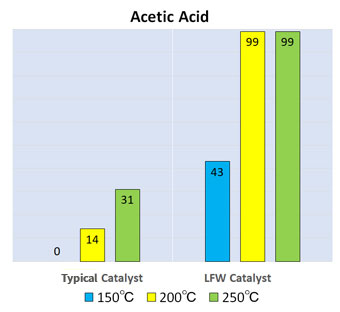

Catalyst Performance Diagram

Destruction and removal efficiency (%) at each temperature for typical catalysts and LFW catalysts:

Under 250 ℃, LFW catalysts have a great activity against aldehydes, acetic acid, and Alcohols.

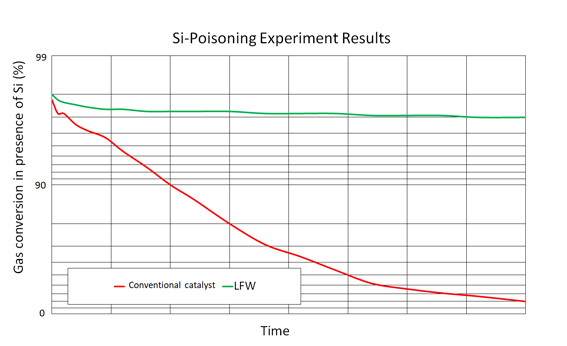

Performance retention while coexisting with organic silicones is significantly extended for LFW catalyst.

Example of Application Fields

- Improving the destruction efficiency as a secondary treatment and effectively removing odors by being installed downstream of any exhaust gas treatment equipment (such as: Catalytic Combustion Systems, Direct Flame Incinerators, Regenerative Catalytic/Thermal Oxidizers).

- Efficiently treating of single gas streams such as formaldehyde or acetaldehyde at low concentration and low temperature.

- Revamping from RTO to RCO. It is possible to consider the use of an electric heater-or even the use of electricity sourced from renewable resources-instead of a gas burner.

- Reducing of the operating temperature of existing catalytic combustion equipment by replacing with LFW.

- Expanding to various applications, such as electric vehicles, semiconductor industry, space business industry and so on.

For inquiries:

| Department | Environmental Catalyst Div. |

|---|---|

| Contact Form | |

| TEL | ARIOKA:+81-90-5398-5199 (Japanese, English) PIET:+81-80-4462-6530 (French, English) *Do not hesitate to reach out to us by using the contact form, we will come back to you as soon as possible. |